Processing technology of liquid pump impeller

Processing technology of liquid pump impeller

Impeller of the liquid pump basically is generally in casting production. The importance of channel geometries may be ignored and it would result in pump flow size and position to achieve the design requirements. In order to ensure the specific requirements of the pump flow, it is necessary to take technical measures for casting error to be corrected when pump mechanical parts is processing.

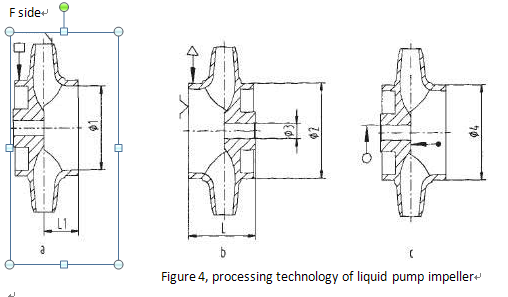

Usually in the first process when it is clamping. It must be based on the pump impeller flow channel to find a positive reference. Figure four, the impeller machining process is as follows:

(a) Firstly you need to find inletφ1 of the impeller and outlet side F. Then four claws clamp ring, rough front mouth ring, inner hole, the car is good outer circle, front cover.

(b) The opposite side with three claw clamps the impeller front end flat, coarse, fine car after the ring, inner hole, car back;

(c) In the end, the inner hole of the shaft is positioned in the front of the inner hole, and the front of the vehicle is in the front of the vehicle, so that the position of the flow passage is well ensured, and the requirement of the front and the back of the ring and the inner hole of the inner hole are ensured.