information

INFORMATIONHOTLINE

+86-0531-85667509T e l:+86-0531-85667509

F a x:86-0531-85667508

E-mai:warwickpump@gmail.com

MOLTEN SALT PUMP

MOLTEN SALT PUMP

MOLTEN SALT PUMP

GENERAL DESCRIPTION

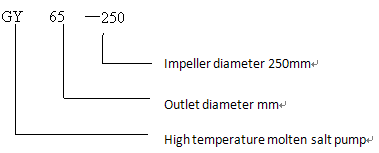

GY type molten salt pump is independently developed series products of the molten salt pump. GY type molten salt pump is designed by Jinan Warwick Pump Co., Ltd. It is on the basis of experience of producing at high temperature liquid pumps and pump of the molten salt solution. It references the same type of foreign products. And it is a molten salt circulation system or molten salt transport of special high temperature pump.

PERFORMANCE

Temperature (T): 180 ℃ ~ 540 ℃

Capacity (Q): 3 ~ 600 m3 / h

Head (H): 10 ~ 70 m

Dielectric viscosity:μ<300cp

APPLICATIONS

FEATURES

GY type molten salt pump is used in conveying high temperature molten salt (nitrate) for melamine project, alumina projects and caustic soda project and other fine chemical industries.

Fifth, structural characteristics

GY type molten salt makes it Stably transport 540℃ high temperature molten salt (nitrate)by using effective cooling means, reasonable structure and materials.

The series of products are the advantages of high efficiency, smooth operation, small vibration, low noise, long life, low maintenance, low maintenance costs and so on. Quality reaches the level of similar foreign products. If you want to know detailed structure of the pump, you can ask Jinan Warwick Pump Co., Ltd.

TYPICAL PERFORMANCE TABLE

|

MODEL |

CAPACITY |

HEAD |

EFF. |

POWER |

LENGTH |

|

GY32-125 |

6.3 |

5 |

45 |

1.1 |

0.8~3.0 |

|

GY32-160 |

6.3 |

8 |

40 |

1.5 |

0.8~3.0 |

|

GY32-200 |

6.3 |

12.5 |

33 |

2.2 |

0.8~3.0 |

|

GY32-250 |

6.3 |

20 |

27 |

4 |

0.8~3.0 |

|

GY50-125 |

12.5 |

5 |

55 |

1.5 |

0.8~3.0 |

|

GY50-160 |

12.5 |

8 |

51 |

1.5 |

0.8~3.0 |

|

GY40-200 |

12.5 |

12.5 |

46 |

3 |

0.8~3.0 |

|

GY40-250 |

12.5 |

20 |

39 |

5.5 |

0.8~4.0 |

|

GY40-315 |

12.5 |

32 |

33 |

11 |

0.8~4.0 |

|

GY65-125 |

25 |

5 |

64 |

1.5 |

0.8~3.0 |

|

GY65-160 |

25 |

8 |

62 |

3 |

0.8~3.0 |

|

GY50-200 |

25 |

12.5 |

57 |

4 |

0.8~3.0 |

|

GY50-250 |

25 |

20 |

50 |

7.5 |

0.8~4.0 |

|

GY50-315 |

25 |

32 |

48 |

15 |

0.8~5.0 |

|

GY80-125 |

50 |

5 |

69 |

3 |

0.8~3.0 |

|

GY80-160 |

50 |

8 |

68 |

4 |

0.8~3.0 |

|

GY65-200 |

50 |

12.5 |

68 |

5.5 |

0.8~4.0 |

|

GY65-250 |

50 |

20 |

63 |

11 |

0.8~5.0 |

|

GY65-315 |

50 |

32 |

58 |

18.5 |

0.8~5.0 |

|

GY100-200 |

100 |

12.5 |

73 |

15 |

0.8~5.0 |

|

GY100-250 |

100 |

20 |

72 |

18.5 |

0.8~5.0 |

|

GY100-315 |

100 |

32 |

65 |

45 |

1.2~6.0 |

|

GY100-400 |

100 |

50 |

55 |

55 |

1.2~6.0 |

|

GY125-250 |

200 |

20 |

77 |

30 |

1.2~6.0 |

|

GY125-315 |

200 |

32 |

75 |

45 |

1.2~6.0 |

|

GY125-400 |

200 |

50 |

70 |

90 |

1.2~8.0 |

|

GY150-250 |

400 |

20 |

79 |

75 |

1.2~8.0 |

|

GY150-315 |

400 |

32 |

79 |

90 |

1.2~8.0 |

|

GY150-400 |

400 |

50 |

78 |

132 |

1.2~8.0 |