information

INFORMATIONHOTLINE

+86-0531-85667509T e l:+86-0531-85667509

F a x:86-0531-85667508

E-mai:warwickpump@gmail.com

Technology article

Standard High Temperature Pump Designs

When dealing with high temperature molten salt applications, pumps can be categorized into four different styles. There are other types of high temperature liquids, such as molten metals, which use the same type of pump or even several other types, such as EM (Electro-Magnetic) pumps which cannot be used on molten salts.

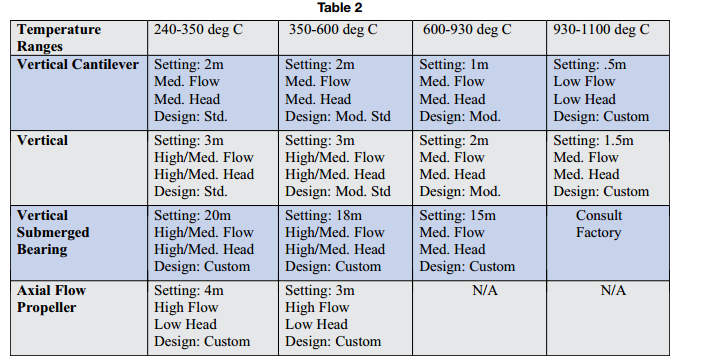

Table 2 lists standard vertical pumps for molten salt applications and gives general data that is not related to any specific application.

Vertical cantilever pumps offer many different features, such as several types of mounting arrangements. System designers have great flexibility in tank mounting, as well as mounting the pump outside of the tank. Vertical cantilever pumps have no bearings below the main mounting plate. Cantilever pumps only offer single volute designs. The disassembly of a vertical cantilever pump is the easiest of all four designs.

Vertical pumps can be single stage or multi-stage wet end designs. Applications requiring high heads will use multi-staged wet end. Multi-staged wet end designs are custom manufactured for molten salt applications. These pumps have a lower radial bearing. They also have several mounting arrangements, both inside the tank and outside of the tank. Vertical pumps can offer multi stage volutes as an option. They have longer settings than the cantilever, but are more difficult to disassemble. Vertical submerged bearing pumps offer the longest design. They can only be mounted in the tank.

Vertical submerged bearing pumps can offer multi-staged volutes. These pumps are the most difficult to disassemble.

Axial flow pumps are special in design. Their applications are limited to low heads and high flows. Chemical reactors are one of the main applications for this type of pump. Their special design permits the rotating assembly to be removed from the pump shell without removing the suction and discharge piping. Axial flow pumps can only be mounted with the shaft in a vertical up position. The disassembly of this pump makes it one of the easiest pumps to rebuild.